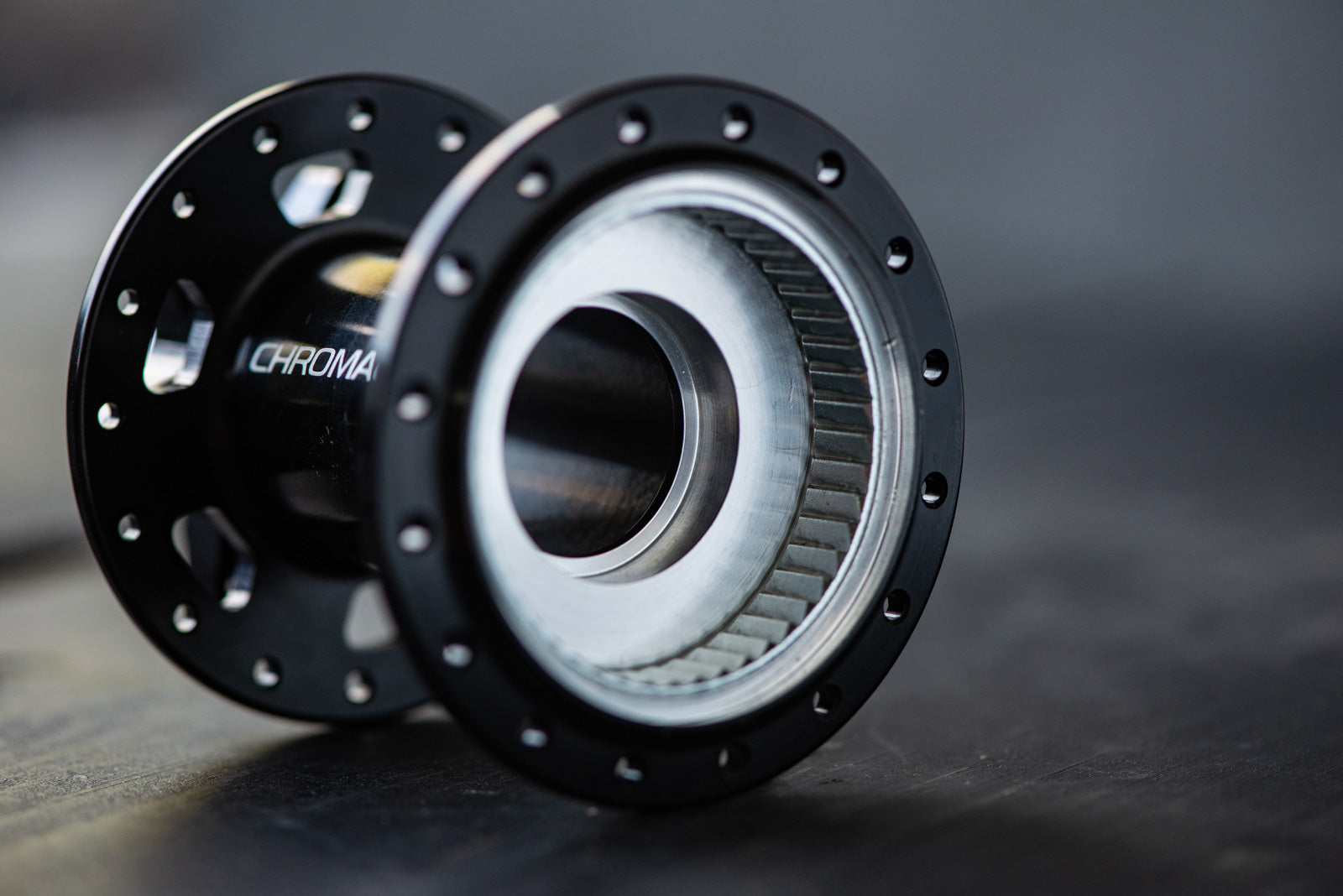

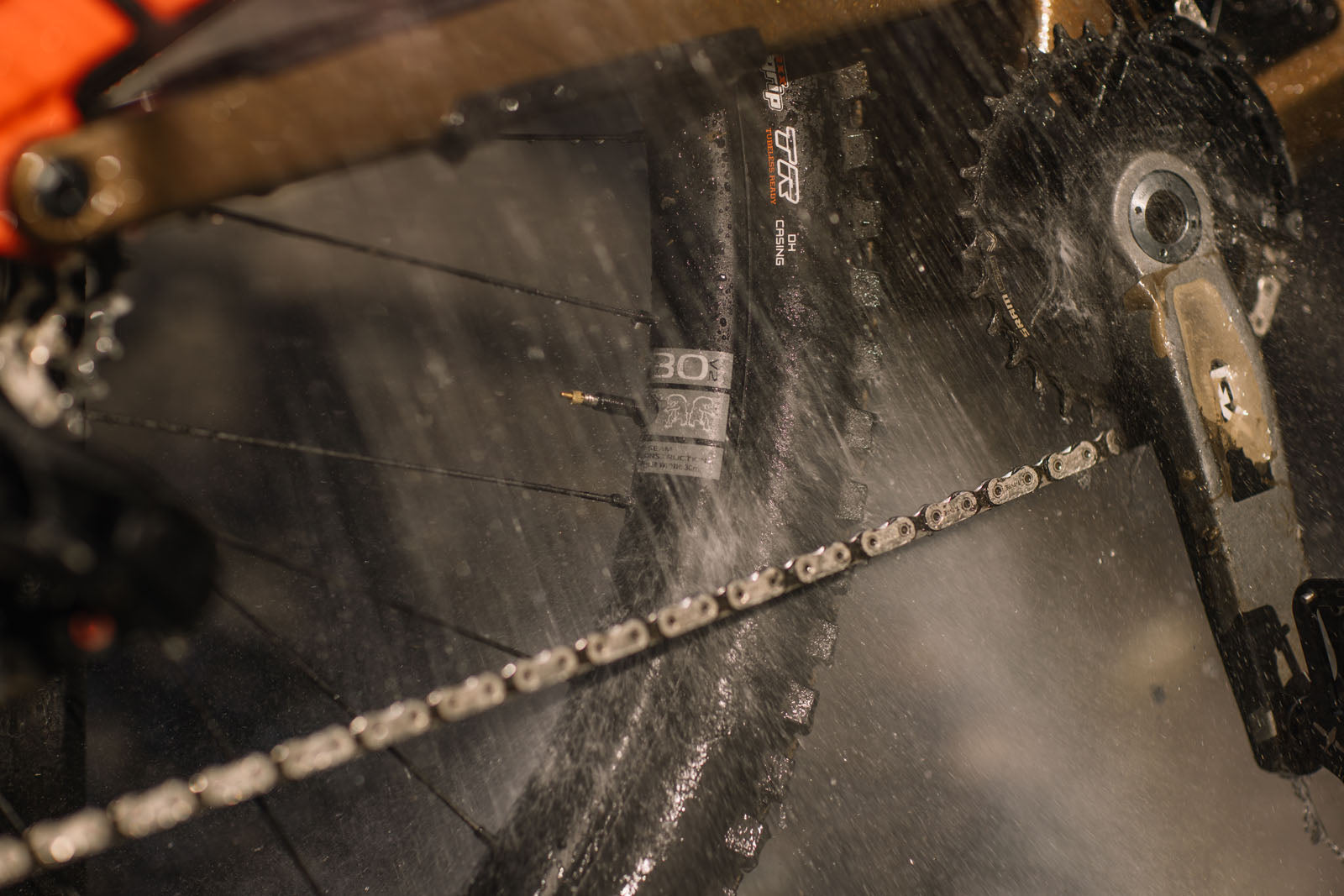

Our burliest rim laced to our best ever hub with a massive 96POE.

BA30v2/R6 Rear Wheel

Aggy Rides the new wheels

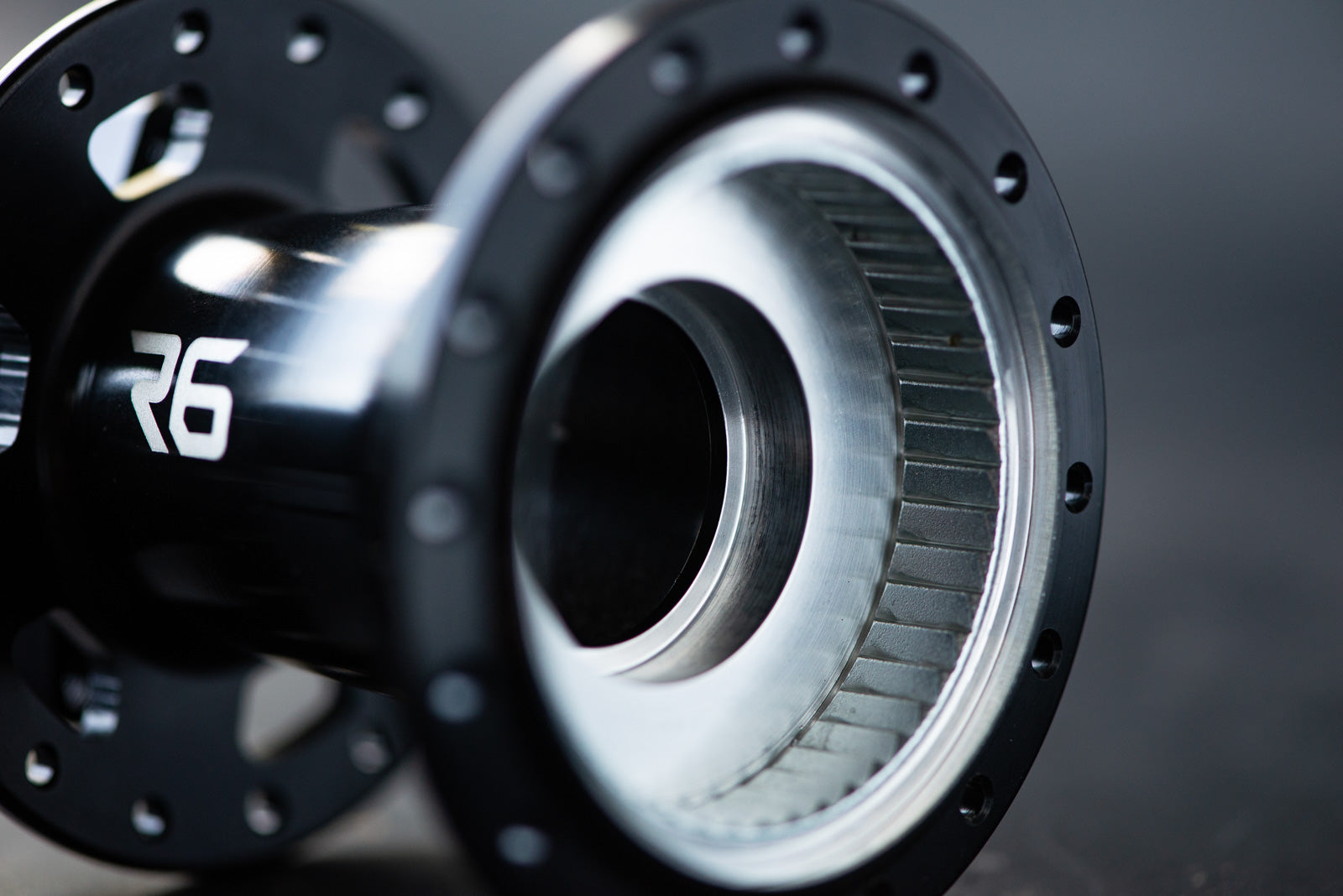

R6 Specs

Material // 6061 Aluminium

Finish // Anodised

Hole count // 32

Axle diameter // 12mm

Spacing // Boost 148mm

Disc mount // 6 Bolt

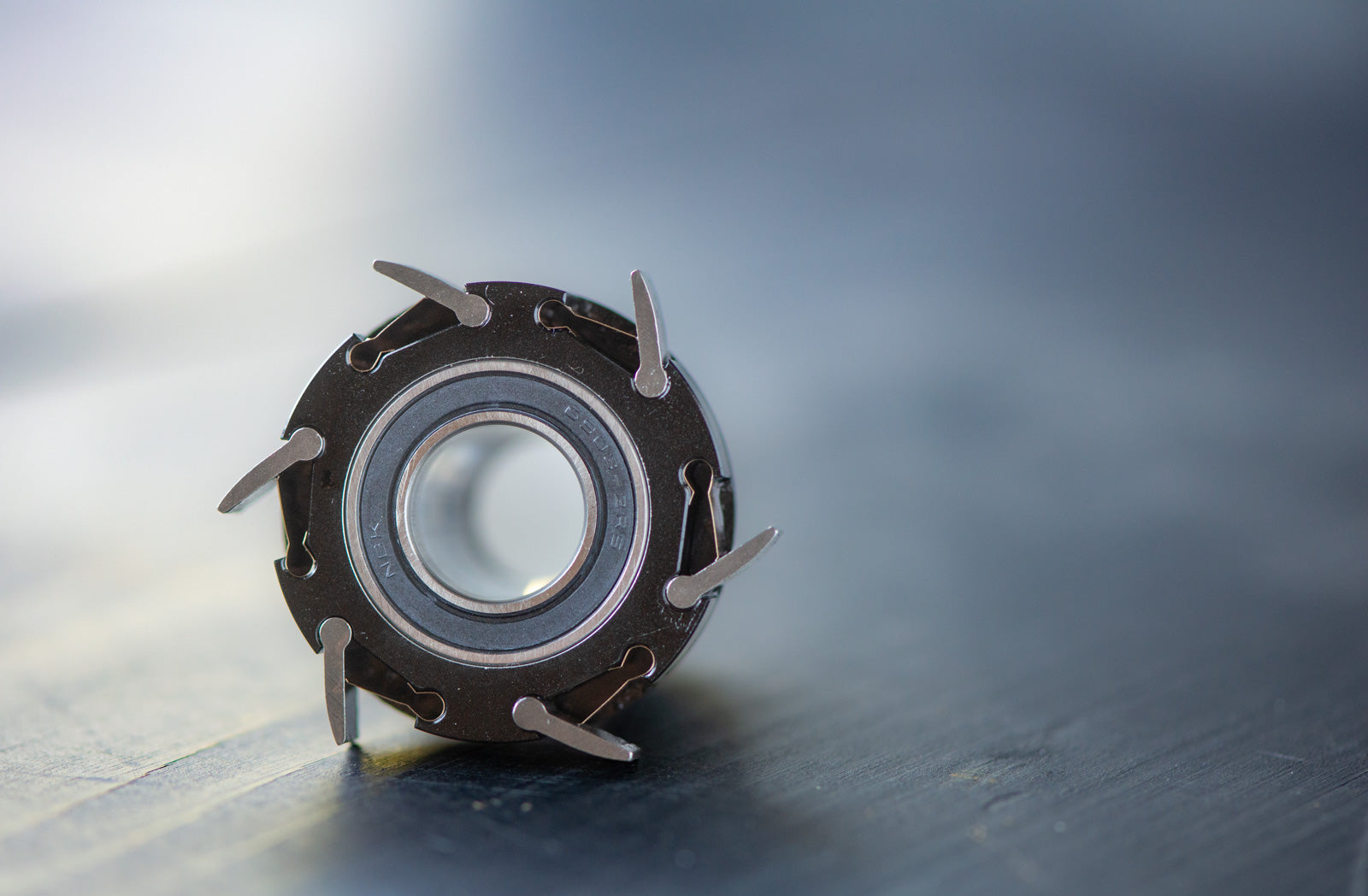

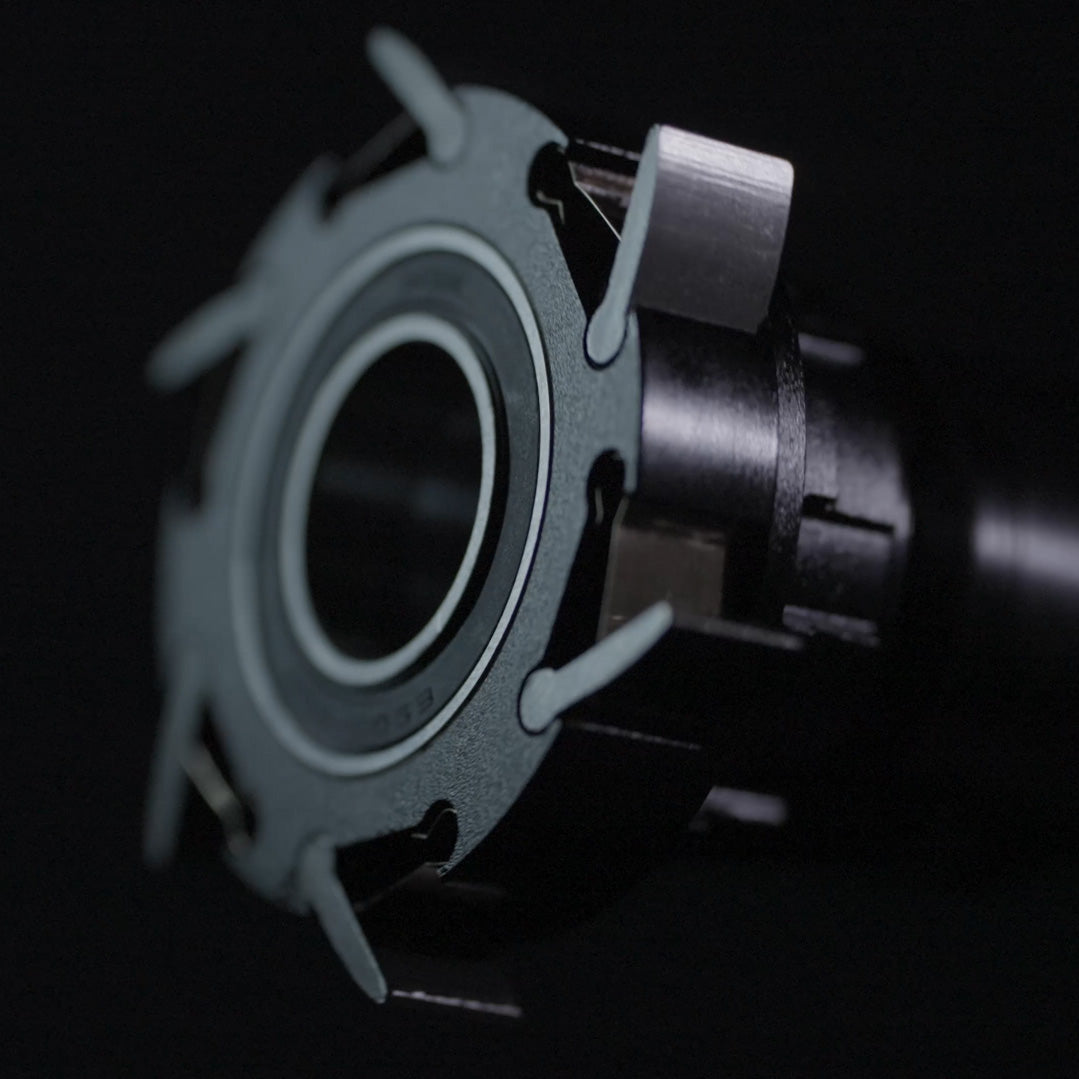

Engagement // 6-pawl 96 Point

Driver // XD, HG, Microspline

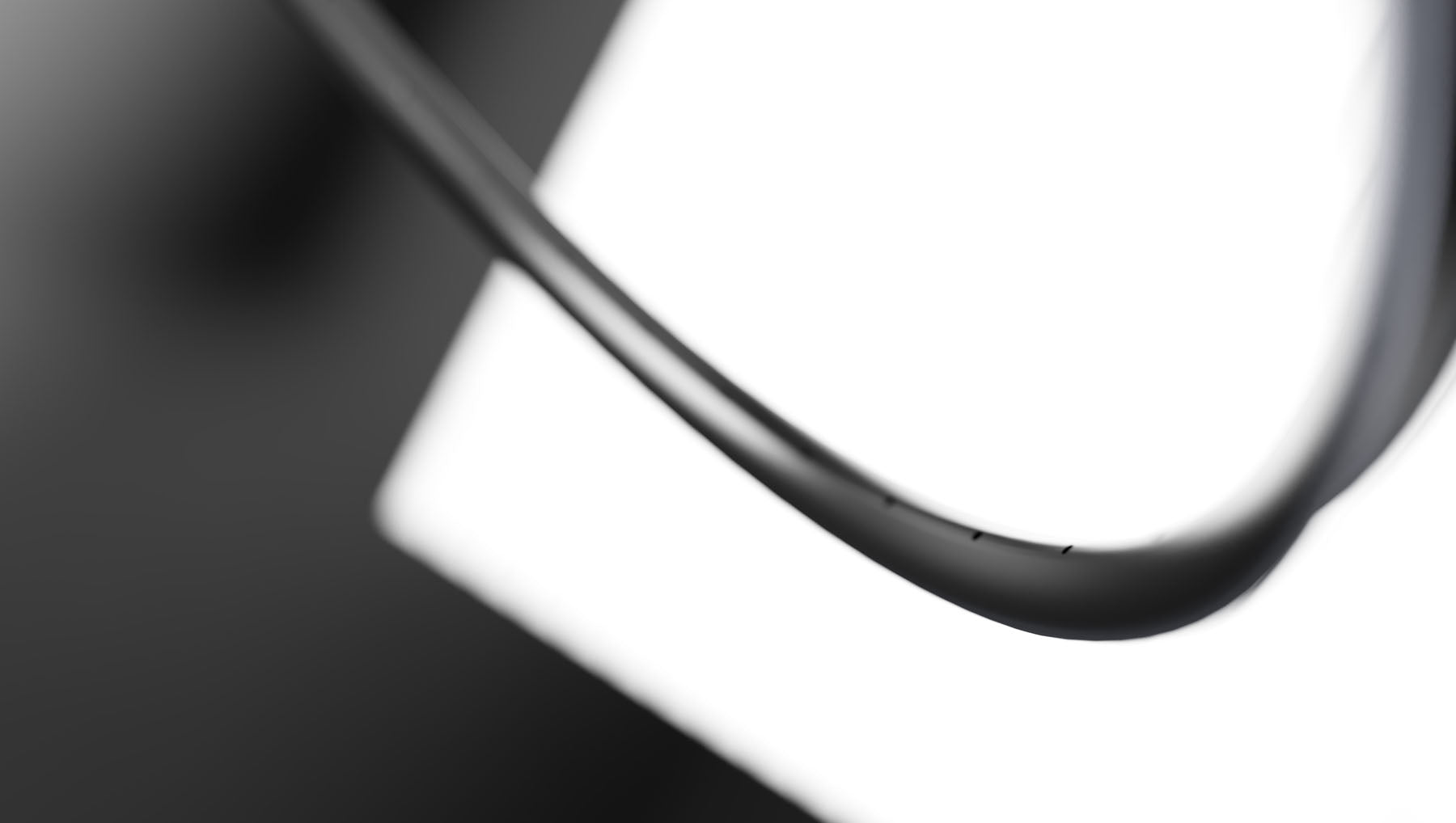

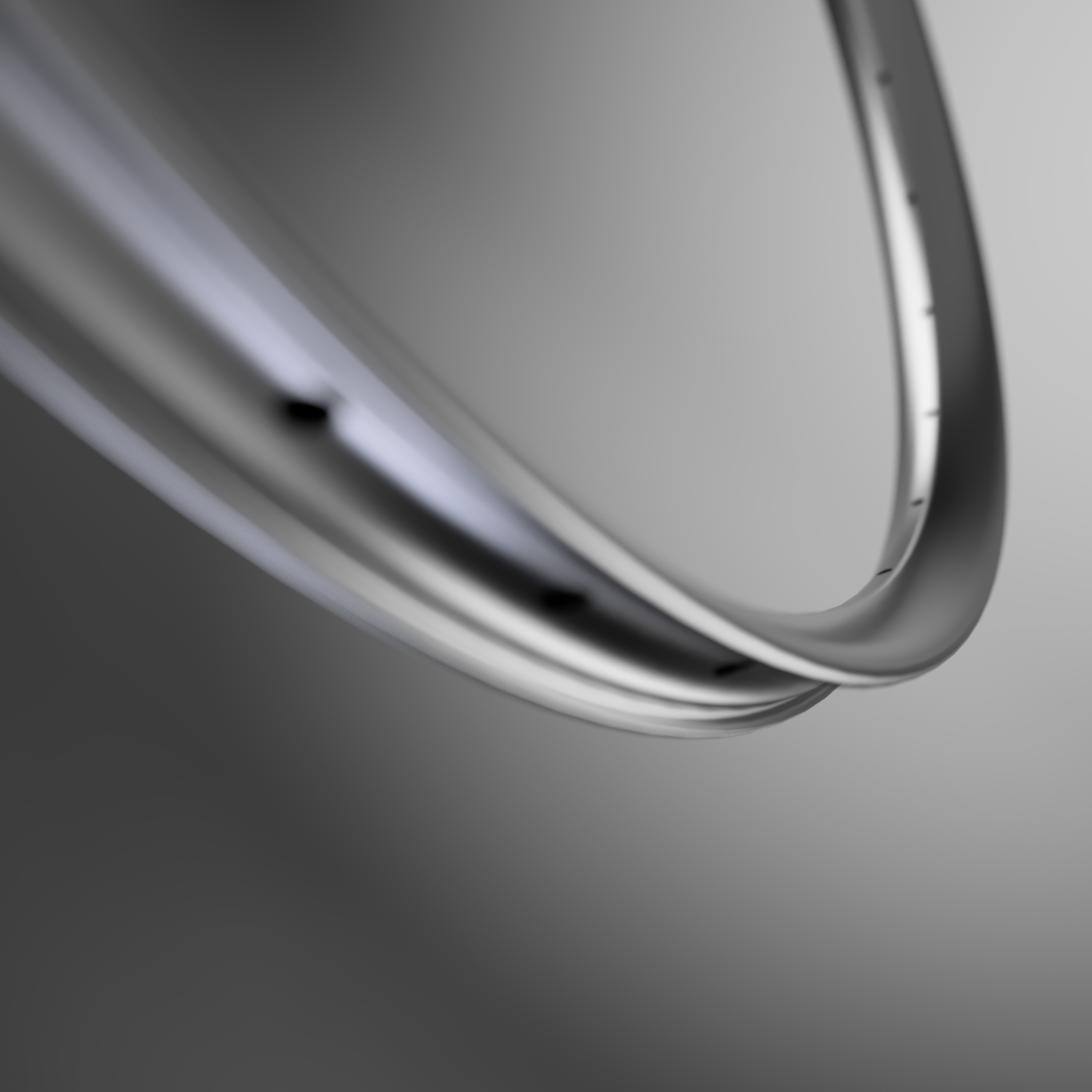

BA30v2 Specs

Material // Premium extruded alloy

Finish // Fusion welded seam-ground finish

Profile // V2 Cavity / Impact resistant design

Tubeless // Tubeless Ready

Rim Weight // 27.5: 610g / 29: 640g

Internal Width // 30mm

Valve // Presta

Max Tire Pressure 2.4" // 45PSI

Max Tire Pressure 2.8" // 30PSI

Max Spoke Tension // 125KgF

Build Info // 27.5" ERD: 563mm / 29" ERD: 600mm

Hole Count // 32

Wheel FAQ's

We have made several big improvemments while developing the R6. Most notably the POE goes from 36 to 96, which you will instantly notice when ratcheting up nasty climbs.

We have also done a lot of work on the bearing tolerances and sealing to create an incredibly free spinning hub.

The v2 has been refined in several key areas while maintaining the same weight. It has a 20% more impact resistant sidewall, with re-distributed material for more vertical resilience and increased lateral compliance.

We have increased the bead wall thickness for increased pinch flat protection, as well as making the central channel wider for easier tire installation.

The Ally is our most economical rim. Slightly heavier and not quite as strong as the rest of the lineup, due to it's pinned construction and more economical alloy.

The Phase balances strength/weight, which is a great choice if you're not a wheel destroyer and/or weight is a priority.

The BA v1 was our burliest rim offering, but the v2 has surpassed it in terms of strength while adding no extra weight.

Wheels come pre-taped with tubeless valves installed.

All you need to do is install tires and sealant.

Our wheels are pre-stressed and ready to ride out of the box.

However, like all wheels there is a bedding-in period, so be sure to keep an eye on spoke tension after the first few rides.

Provided the rim does not have a crack, you can use an adjustable wrench to gently bend it back to help your tyres seat properly. Use a rag or an old inner tube to prevent scratching your rim, and be careful to avoid puncturing your rim tape!

You'll likely need to adjust spoke tension if your wheel has taken a hit hard enough to dent it.

A freehub clean and re-grease should be done approximately every 500km or 6 months. We have designed the R6 to be very easy to work on and you can perform this service tool-free. Obviously if you like to ride underwater through sand, you might need to do this more often.

For main bearings, these should be replaced when required, not at specified time intervals (sort of like how we couldn't tell you how often to change your tyres). The bearings should spin smoothly by hand and not make any grumbling noise or have side to side play. You can spin your wheel and hold onto your fork leg or seat stay (watch your fingers!) to try and feel any unwanted grumbles.

We will have bearings available to buy as well as some simple tools to make your life a whole lot easier.